Project Profile

Name: Western Main Bridge of the Changjiugang Railway Yangtze River Gan River Combined Road-Rail Bridge

Status: Under construction

Location: Jiangxi Province

Length: Main span 320m, total length 706m

Type: Combined road-rail double-deck harp-shaped cable-plane box girder composite beam cable-stayed bridge

Features: World’s first 350 km/h combined road-rail double-deck bridge, world’s first 350 km/h harp-shaped cable-plane cable-stayed bridge

Project Owner: Changjiugang Intercity Railway Co., Ltd.

Designer: China Railway Fourth Survey and Design Institute Group Co., Ltd.

Contractor: China Railway Major Bridge Engineering Group Co., Ltd.

Supervision: China Railway Fourth Survey and Design Institute (Hubei) Engineering Supervision Consulting Co., Ltd.

The Western Main Bridge of the Changjiugang Railway Yangtze River Gan River Combined Road-Rail Bridge spans the western branch of the lower Gan River, a Class II navigable waterway. It adopts a (48+144+320+144+48) m harp-shaped cable-plane box girder composite beam cable-stayed bridge configuration, with a total length of 706m. The main girder features a box girder composite beam structure with large cantilevers on both upper and lower decks. The bridge tower incorporates decorative text elements in its curved design. The stay cables are arranged in a uniform harp shape across the entire bridge. The bridge has the following key characteristics:

Unique Features

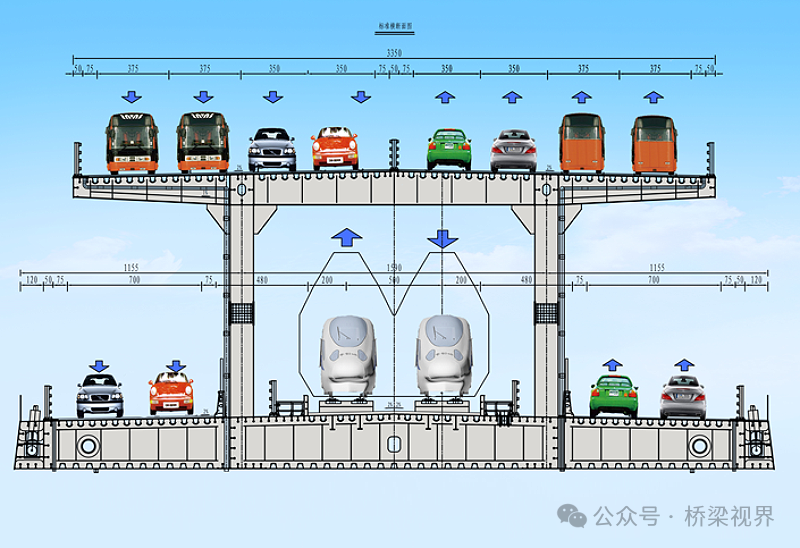

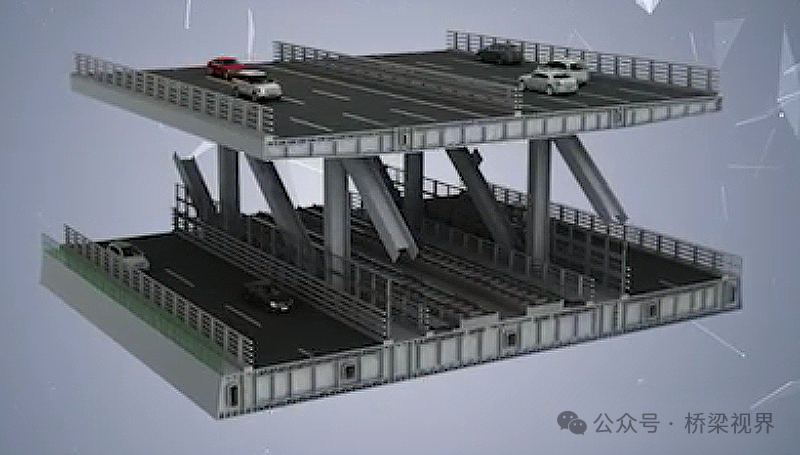

1. Multi-modal double-deck design with complex traffic organization The upper deck is designed for an 80 km/h urban expressway, while the lower deck accommodates a 60 km/h urban arterial road and a 350 km/h double-track high-speed railway. This multi-functional shared corridor design maximizes the use of passage resources and reduces project investment.

2. Innovative bridge structure, setting multiple world records The bridge becomes the world’s combined road-rail bridge with the highest number of road lanes and the largest traffic capacity. It is also the world’s largest-span 350 km/h combined road-rail double-deck bridge and the world’s first 350 km/h harp-shaped cable-plane cable-stayed bridge. It introduces a novel large-cantilever road-rail double-deck steel truss girder cross-section.

3. Challenging construction conditions with multiple constraints The bridge site is a habitat for finless porpoises, prohibiting underwater blasting. The riverbed has a thin overburden layer, with pile caps embedded up to 5m into bedrock with a maximum compressive strength of approximately 30MPa, increasing the difficulty of cofferdam installation and foundation excavation. The main girder segments are 16m long, 15.5m high, and weigh up to 958 tons, posing transportation challenges due to the 10m height restriction of the navigation channel.

4. High operational safety requirements for 350 km/h high-speed railway The ballastless track 350 km/h high-speed railway imposes stringent requirements on the bridge’s structural stiffness, creep deformation, temperature deformation, dynamic performance, as well as the safety and stability of high-speed train operations and passenger comfort.

5. Integrated structural and aesthetic design creating a landmark The tower design incorporates elements of traditional architectural gateways and Chinese calligraphy, aligning with Nanchang’s status as a historical and cultural city. The ancient character “昌” (Chang) forms the main tower’s crossbeam structure, symbolizing both the expansion of Nanchang and prosperity. Unlike traditional cable-stayed bridges, the stay cables are arranged in a harp shape, distributing forces evenly along the tower and creating a more streamlined appearance. The parallel cables resemble harp strings, symbolizing the harmonious development of central Jiangxi. This design integrates structural efficiency and aesthetic appeal to create a landmark for the Ganpo region.

Innovations

1. First proposal of a cable-truss co-linear harp-shaped cable-plane box girder composite beam cable-stayed bridge, featuring a novel structure, aesthetic design, efficient force transmission, rational load distribution, high longitudinal, transverse, and vertical stiffness, minimal girder end displacement, and good adaptability for ballastless track.

2. First application of a road-rail double-deck steel truss girder cross-section with large cantilevers on both upper and lower decks. Compared to traditional wide double-main-girder cross-sections, this design eliminates cross-bracing and additional vertical members, resulting in a simpler structure. It reduces out-of-plane bending moments in web members by 2/3 and significantly decreases girder end rotation and vertical displacement. It also allows for physical separation between road and rail traffic, reducing interference.

3. First use of a longitudinal elastic restraint system in a cable-stayed bridge, enabling coordinated deformation under temperature effects, reducing main girder end longitudinal displacement and tower base bending moments. The elimination of dampers reduces maintenance requirements for the main bridge support system and lowers project costs.

4. Development of a multi-functional safety isolation facility integrating collision prevention, throw protection, glare reduction, noise mitigation, and wind protection to minimize interference between the 350 km/h high-speed rail and 60 km/h urban arterial road on the lower deck, ensuring safe operation of the combined road-rail bridge.

5. Innovative use of interlocking steel pipe pile cofferdams for main bridge piers, combining rotary drilling for pilot holes, backfilling with fine sand, and high-pressure jet grouting to solve anchoring and water-sealing challenges in shallow overburden and high-strength bedrock. This approach avoids traditional underwater blasting and hole expansion, reducing construction risks and protecting the ecological environment.

6. Development of a new steel girder launching technique using a stepper and slider system, utilizing friction coefficient differences between materials to achieve smooth girder launching. Introduction of a method for stacking, lifting, and installing steel girders in layers to overcome the 10m height restriction of the navigation channel.

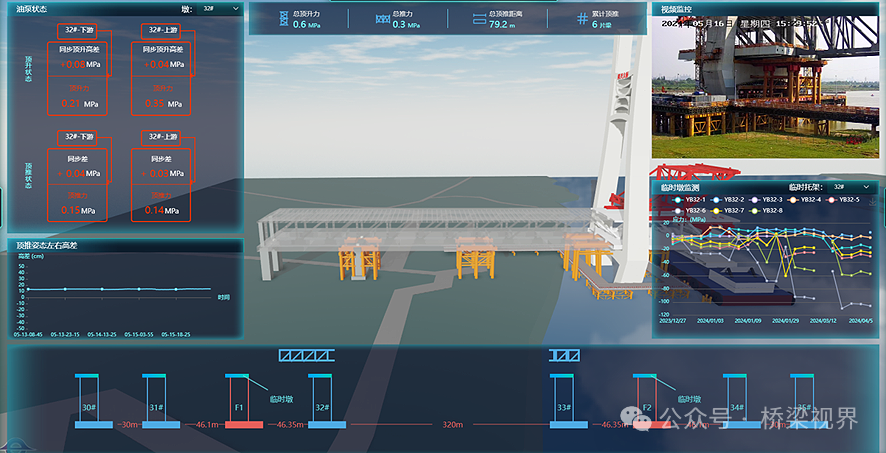

7. Implementation of intelligent construction techniques for the harp-shaped box girder composite beam cable-stayed bridge, enabling dynamic and intelligent monitoring of the entire bridge construction process. Utilization of smart, information-based control methods to digitize construction elements and processes, combining scientific “measurement,” “calculation,” and “control” procedures to transform traditional manual supervision into an automated system for data collection, adjustment, and instruction output, ensuring construction safety and efficiency.