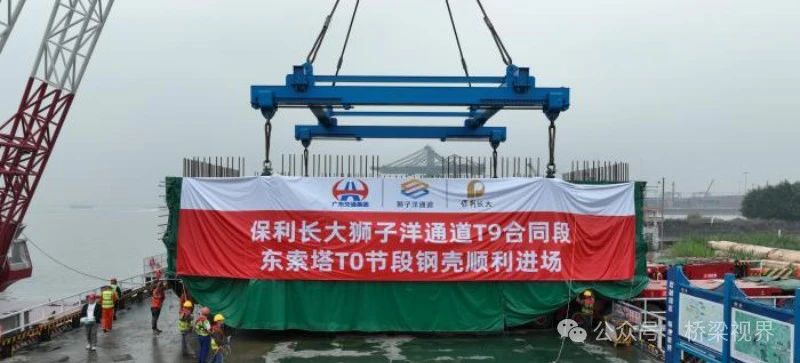

On March 16th, the steel shell of the T0 segment of the east cable-stayed tower of the Lionchor Bridge was successfully hoisted into place, marking a new major progress in the construction of the Lionchor Bridge.

As a key control project of the Lionchor Channel, the Lionchor Bridge has a unique design and high technical difficulty. The bridge adopts a design of a “spanning the river in one go” with a main span of 2,180 meters and a double-layer steel truss cable-stayed bridge, with a total of two main towers set up. Each main tower is composed of 124 steel shell segments and 6 steel crossbeams from bottom to top, with each segment bearing important structural functions.

The first steel shell segment of the Lionchor Bridge that was hoisted into place this time weighs about 119 tons, is about 17.5 meters long, 12.6 meters wide, and 3.6 meters high, adopting a single-box three-chamber cross-section structure. To successfully lift the “steel iron beast” weighing hundreds of tons, the project deployed an R6600-240 super large tower crane with a designed independent height of 92.5 meters, a jib length of 70 meters, and a maximum lifting capacity of 240 tons.

It is reported that facing the lifting weight of over 100 tons, the project adopted an advanced and safe lifting process during the hoisting operation. This time, the steel shell was hoisted ashore by the lifting ship “Yuedongwan 0096”, lifting the steel shell from the water onto land. Subsequently, the steel shell was transported to the designated location using a module vehicle. Next, through the precise operation of the R6600-240 tower crane, the steel shell was hoisted to a temporary storage point.

The waters where the hoisting operation took place are adjacent to the Guangzhou Port small vessel recommended navigation channel and the Fifth Warning Area, with heavy vessel traffic and a complex navigation environment, posing a significant impact on navigation safety. The relevant responsible departments provided guidance to the owner unit in advance to formulate a navigation safety assurance plan, put forward safety supervision suggestions, and coordinate on-site traffic diversion. On the day at 17:00, after 10 hours, the two pieces of the T0 segment steel shell were successfully hoisted into place.