As an ancient bridge form, the arch bridge is the structural form that has undergone the most changes among all bridge systems. Due to the continuous enrichment of structural forms and construction methods, arch bridges can be applied to bridges ranging from over 500m to less than 100m. There are structural forms suitable for mountainous areas as well as those suitable for plains; they are applicable to highways, urban bridges, and also railway bridges; they are widely used in mountain canyons and are also commonly seen over rivers and oceans. Ancient and modern arch bridges are scattered all over the world, and are still flourishing to this day, occupying an important position in bridge construction.

From the perspective of the technical development of arch bridges, the emergence of new materials, new theories, new processes, and new equipment has greatly promoted the development of the arch bridge system and construction technology, resulting in a wide variety of arch bridge forms. In view of the development needs of China’s transportation infrastructure, a large number of bridge engineering projects still need to be constructed. From both a technical and aesthetic perspective, arch bridges are an indispensable and important component. China has a vast territory and diverse bridge construction environments. When facing a series of specific requirements such as different spans, different terrains, and different construction conditions, how to innovatively seek the best solution that perfectly combines strength and beauty becomes the most meaningful work for builders.

Some say that arch bridges are inherently beautiful, with the beautiful main arch curve embodying a powerful force and a sense of spanning. With the progress of the times and technological developments, modern arch bridges have taken on myriad structural forms and are widely applied both domestically and internationally, among which there are many outstanding works that perfectly combine strength and beauty. Drawing fully on domestic and international achievements and experiences is of great practical significance for the comprehensive development of arch bridge technology and art.

Upper Supported Arch Bridges

At bridge sites with suitable geological conditions in mountainous areas and islands, concrete arch bridges have strong competitiveness, which is not only reflected in technical and economic indicators, but also often manifested in the aesthetic value of the bridges. The well-known Salginatobel Bridge in Switzerland (Figure 1), designed by Swiss engineer Robert Maillart in 1930, is a sickle-shaped upper supported arch bridge spanning a valley. The 90m main span is a three-hinged hollow box arch, constructed using the cantilever method. This bridge was evaluated as the most beautiful bridge in the world in the 20th century.

As arch bridge technology progressed, the world span record for concrete arch bridges has also been continuously broken. The KRK Bridge in Croatia (Figure 2), completed and opened to traffic in 1980, connects the island of St. Marco and the island of Krk with the mainland. Bridge No. 1 has a main span of 390m, and Bridge No. 2 has a main span of 244m, both of which are upper supported reinforced concrete arch bridges. The arch rings adopt a single-box three-cell reinforced concrete cross-section. The construction of the large bridge innovatively adopted the cantilever truss assembly method. The arch rib of Bridge No. 1 is 6.0m high with a height-to-span ratio of 1/65, while the arch rib of Bridge No. 2 is 4.0m high with a height-to-span ratio of 1/61. The graceful arch curves and the linear beam-column elements, with the double arches arranged in intervals, present an elegant rhythm of rigidity and flexibility.

The Almonte Viaduct in Spain (Figure 3), completed in 2016, is 996m long and carries high-speed trains across the Almonte River. The main arch span is 384m, and the main arch rise is 67.5m, with a rise-to-span ratio of 1/5.7. In order to meet the requirements of railways for lateral stiffness and project economy, the main arch adopts a separated double-box cross-section in a basket-handle arrangement, with the two arch ribs merging into one at the crown. The arch rib cross-section is 6.9m high with a height-to-span ratio of 1/55.7 at the springing, and 4.8m high with a height-to-span ratio of 1/80 at the crown. The superstructure above the arch is a statically indeterminate structure, with a span arrangement of (45+7×42+45)m and a prestressed concrete box girder cross-section. To improve the longitudinal stiffness of the superstructure and resist the braking force of trains, it is rigidly connected to the arch rib cross-section over a length of 17m near the crown, forming an integral cross-section. The structural treatment is simple and exquisite. The girder and arch are longitudinally rigidly connected at the crown, and the basket-handle arrangement of the arch ribs in the transverse direction forms a triangular shape, giving a strong sense of force and stability, embodying the perfect combination of strength and beauty. The soaring main span is awe-inspiring.

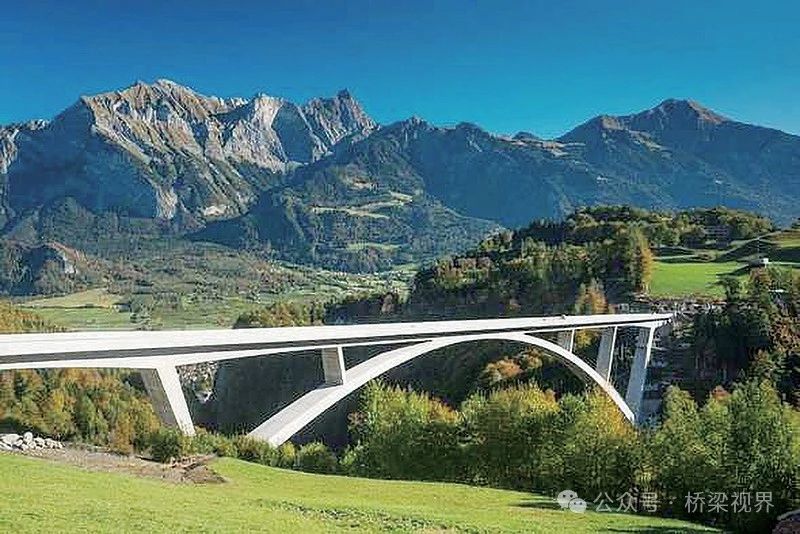

The Tamina Valley Bridge in Switzerland (Figure 4) is located in the southern part of the canton of St. Gallen. The deep-cut valley through which the Tamina River flows separates the plateau and its inhabitants. In 2005, the local authorities decided to build a bridge. In order for the large bridge to better integrate into the natural environment, it was most important to handle the sensitive elements of the surrounding and local environment properly. In addition, this valley is a protected habitat area, with the area under the bridge belonging to the ibex protection area, requiring that the impact on natural resources be minimized during construction. The local authorities held an international design competition, and the proposals had to meet the standards of technical feasibility, outstanding appearance, and economic practicality. In the end, the inclined arch + inclined piers above the arch proposal won first place in the competition. The total length of the superstructure of the large bridge is 414m, and the width is 9.5m. The main arch span is 260m. The springings of the two half-arches are not at the same elevation. In order to ensure that the horizontal thrusts at the two crowns are equal, the two half-arches adopt different spans and rise-to-span ratios. The inclined piers are rigidly connected to the arch girder, and concrete hinges are provided at the short piers to release the excessive bending moments caused by temperature effects.

The structure of the large bridge is transparent, simple, and elegant, with convenient construction and economical cost. The innovative structural design of the large bridge gives a fresh impression and brings more aesthetic appeal to the bridge.

The Henrique Bridge in Portugal (Figure 5), completed in 2002, is currently the longest span of a through arch bridge. The total length of the large bridge is 371m, with a main span of 280m and a total deck width of 20m. The main arch ring adopts an equal-height, variable-width box structure, with an arch height of 1.5m. The main girder adopts a prestressed concrete single-cell box girder, with a girder height of 4.5m. In the 70m-long segment within the mid-span range, the main arch and the main girder are combined into a 6m-high box structure, with a self-weight per meter only half of that of other segments, greatly reducing the self-weight of the structure. The large bridge is a stiff girder-flexible arch (through arch) structure. The deck is subjected to forces similar to an elastically supported continuous beam, playing a significant role in resisting vertical loads, thereby avoiding excessive deviation of the arch’s pressure line from the arch axis under live loads, which is beneficial for the structural force transmission.

The through arch is no longer a typical arch bridge in which the arch is the main load-bearing component and the superstructure above the arch is the force transmission structure. However, it still fully utilizes the role of the arch. Although the Henrique Bridge is not the first arch bridge to adopt the through arch system, the perfect integration of the large bridge with the natural environment, the relatively large main span, and the relatively small rise-to-span ratio give people a strong, counter-intuitive impression and a sense of power and awe, creating an extraordinary experience.

Steel arch bridges occupy an important position in modern bridge construction, and have experienced rapid development since the early 20th century, including some bridges with global influence. The New River Gorge Bridge in the United States (Figure 6), which opened to traffic in 1977, spans the New River Gorge in West Virginia. The total length of the bridge is 924m, with a main span of 518m and a rise-to-span ratio of 1/4.6. The main arch structure adopts U.S.S. low-alloy high-strength steel, which has good corrosion resistance and improves the life-cycle economy. The deck system’s main girders adopt a continuous steel truss structure, and the piers above the arch adopt frame columns, with a maximum height of 122m. The structure of the large bridge is light and elegant, with good transparency, completely devoid of any feeling of heaviness or clumsiness. The shape and color of the large bridge maintain harmony with the surroundings, blending well with the mountain and water elements in the environment.

The Rainbow Bridge (Figure 7), which opened to traffic in 1941, spans the Niagara River and has four vehicle lanes and a pedestrian walkway. The total length of the bridge is 442m, with a main span of 289.5m. The main arch adopts a hingeless steel box-rib arch, with a transverse spacing of 17m between the two ribs, and a rib height of 4m with a height-to-span ratio of 1/72. The two ribs are connected by upper and lower K-bracing. The large bridge is located near the Niagara Falls, with graceful lines and a subdued color, spanning the river valley and blending into the natural environment.

The Tatara Bridge in Japan opened to traffic in 2019 and is an upper supported steel box arch bridge, with a main arch span of 210m and a rise-to-span ratio of 1/11, making it a very flat arch bridge. Constrained by the terrain and road alignment, the bridge deck is on a curve. The large bridge adopts a special basket-handle arch bridge form, with a difference in elevation between the arch springings. The two halves of the main arch ribs are asymmetrical in the transverse direction, with the main girder in plan being a curve of R=1700m and a longitudinal grade of 3.84%. The height of the arch rib cross-section is 2.5m, with a height-to-span ratio of 1/84. The bridge design considered reducing the sense of oppression (bridge form, structural framework, details, and colors, etc.), minimizing the changes to the construction site terrain. To reduce the visual impact of the bridge, the number of components for the piers and lower lateral bracing structure was minimized, and the arrangement was simplified. In the selection and design of the bridge form, factors such as the integration of the bridge with the canyon terrain and avoiding obstructing the horizon behind were fully considered, aiming to minimize the negative impact on the value of the scenic area itself.

Through Arch Bridges

Through arch bridges are widely used, with relatively fewer concrete through arch bridges. Among them, the New Svinesund Bridge in Norway (Figure 9), which opened to traffic in 2005, is an outstanding representative in terms of structure and aesthetics. During the conceptual design stage of the large bridge, architects and bridge engineers worked closely together, with the architectural concept challenging the bridge engineers, resulting in a unique structure that became a landmark building in the local area.

The main arch span is 247.3m. Through careful study of the aesthetics and structure of the arch, the architects hoped to make the arch ribs as slender as possible. In order to improve the lateral stability and buckling resistance of the structure, compared to a separate freestanding arch, the arch ribs are fixed to the deck structure (main girder), significantly reducing the lateral displacement of the arch ribs and increasing the overall stability. The single-piece central arch scheme increased the visibility of the structural components, with no vertical piers below the deck, and a continuous arch structure between the separate steel box girders. These measures made the bridge structure simple and clean, with clear lines visible from all angles. The innovative structural system and form of the large bridge highlighted the beauty of the bridge structure, bringing more valuable experiences to the bridge.

The La Vicaria Bridge in Spain (Figure 10) has an arch span of 168m, with the main girder arranged continuously for its full length. Although the span is not large, its composite girder structural form, application of weathering steel, construction method, and slender structural shape are impressive. The height-to-span ratio of the arch rib is 1/140 at the crown and 1/70 at the springing. The extremely slender arch rib also means that the overall structure is relatively flexible, requiring close attention to structural deformations during both construction and service periods. To address this, temporary supports and anchorage systems are provided at the abutments, ensuring load balancing during construction. The bridge is also equipped with damping devices at the abutments, allowing the deck structure to help the arch rib resist asymmetric deformations. To achieve a slender and aesthetically pleasing appearance for the arch rib, the advantages of the composite section are fully utilized. The chamfered corners and grooves in the rectangular arch rib section create a silhouette with contrasting light and dark areas, further accentuating the simple shape and geometric aesthetics of the bridge, especially against the surrounding natural environment.

The Tenryu Bridge in Japan, with a main arch span of 350m using a through arch bridge with steel arches, was completed and opened to traffic in May 2018. The side spans adopted prestressed concrete T-rigid frames, forming a special structure of a hybrid beam combined with steel girders. The T-rigid frames were constructed using the cantilever method. The self-weight of the upper arch girder is directly borne by the rigid frame piers, not only reducing the vertical load on the main arches, but also arranging the main girders of the arch span and side spans continuously, improving the load-bearing stability, seismic performance, and riding comfort of the main arches. This optimization of the load-bearing structure reduced the forces on the main arches, with an arch rib height of 2.8m and a span-to-rise ratio of 1/125. The arch columns on both sides of the main arches were eliminated, making the bridge structure concise and elegant. The clear, reasonable, and reliable structural system fully exhibits the structural beauty of the bridge.

The above three through arch bridges are all thrust arch bridges. There are also many classic examples of partial thrust arch bridges that often appear in a three-span form, such as the Fremont Bridge in the United States and the Kizugawa New Bridge in Japan.

The Fremont Bridge (Figure 12) in the United States is a three-span continuous arch bridge with a main span of 382.6m and a total length of approximately 655m. It adopts a tied-arch system, with hinged bearings at the arch feet and main piers to release rotational constraints. The upper orthotropic steel deck carries four traffic lanes and works together with the stringers. The lower reinforced concrete deck slab carries four traffic lanes. The rectangular steel box arch ribs are 1.22m wide, with a web height of 1.17m and a maximum flange thickness of 57mm. By adopting a structural system with the arch ribs tied to the main girders, the structure between the tie points initially functions as a “tied-arch bridge” during construction, where the horizontal forces in the arch ribs are balanced by the main girders and not transferred to the arch feet and piers.

The clear structural system and reasonable construction sequence of the Fremont Bridge achieve the rationality of the main girders and arches primarily bearing axial forces under dead loads, as well as the reasonable distribution of forces among the structural components, reducing unfavorable effects under live loads. The slender arch with a span-to-rise ratio of only about 1/300 provides an extraordinary visual experience.

Three-span continuous arches are often partial thrust arch structures, while non-thrust balanced three-span continuous arches are less common. However, under soft soil conditions, a reasonable choice of the beam-arch combination and construction method can maximize the technical and economic advantages of arch bridges. In addition to economic and constructability considerations, the Kizugawa New Bridge (Figure 13) in Japan also took landscape requirements into account. With a main span of 305m and soft soil conditions, adopting a thrust or partial thrust system would be very uneconomical for the arch bridge. Therefore, a non-thrust balanced arch structure was chosen. A tied-arch system was adopted, with a network of suspenders in the main span and vertical columns in the triangular side areas. The middle portion was assembled as a “tied-arch bridge” structure during erection to take advantage of the load-bearing characteristics of arch bridges. While seeking to reduce the steel consumption of the arch bridge, large segmental components could be erected as a whole. This through arch bridge is the best form considering navigational channel and landscape requirements. Its simple and elegant shape, as well as reasonable spatial proportions, make the bridge rhythmic and graceful.

Deck Arch Bridges

Tied-arch bridges have undergone long-term development, with increasingly diverse structural forms combined with construction methods, continuously creating bridges with lower costs and more elegant appearances. These bridges use structural beauty as the basic aesthetic element, either touching people’s hearts with their light and dynamic lines or providing people with extraordinary experiences and shocks through structural and form innovations.

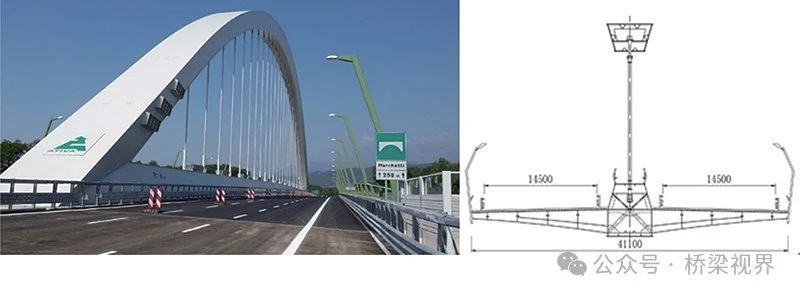

Tied-arch bridges can better showcase their technical and economic advantages when there are height restrictions. The Marche tti Viaduct in Italy, with a main span of 250m (Figure 14), is a tied-arch bridge with a single central arch rib and 26 suspenders between the main girder and arch rib. The bridge has a total width of 41.1m, and the main longitudinal girders are steel box structures, 6m wide and 6.7m high. The top of the steel box is higher than the deck, with the deck height controlled by transverse forces. The strong central steel box girder meets the requirements for longitudinal forces, torsional resistance, etc. The bridge was constructed using the incremental launching method, with the main girders progressively assembled onshore and launched into position. During the main girder construction, arch rib segments were installed on the girders at appropriate times and then lifted into place by cranes as the girders were launched. The bridge rationally selected the stiffness of the girders and arches based on the project conditions, achieving an appropriate distribution of loads between the girders and arches and meeting the requirements for structural form and construction.

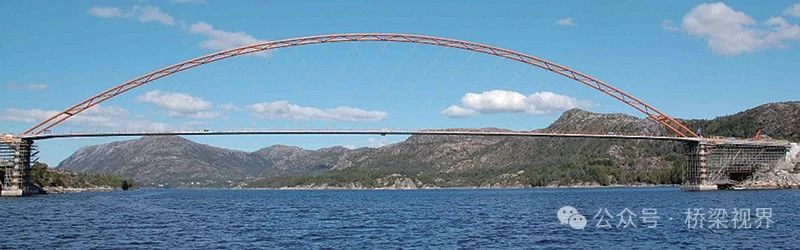

The Brøndøy Bridge in Norway, completed in 2010 with a main span of 220m (Figure 15), features a steel pipe arch rib with an outer diameter of 711mm and wall thickness of 40-50mm. The main girder is a slender prestressed concrete beam with a total width of 7.6m and a 5m wide traffic lane. The suspenders are arranged in a network pattern, anchored at equal distances on the arch rib with an angle of 70° between them. The sum of the arch rib and tie girder heights to the span ratio (λ2) is 1/198. The main span structure weighs only 1860 tons and was constructed onshore before being transported by two floating cranes and installed in position. This bridge astonishingly showcases how the favorable load-bearing behavior of a tied-arch bridge can be achieved with an extraordinarily slender arch and tie girder connected by a network of suspenders.

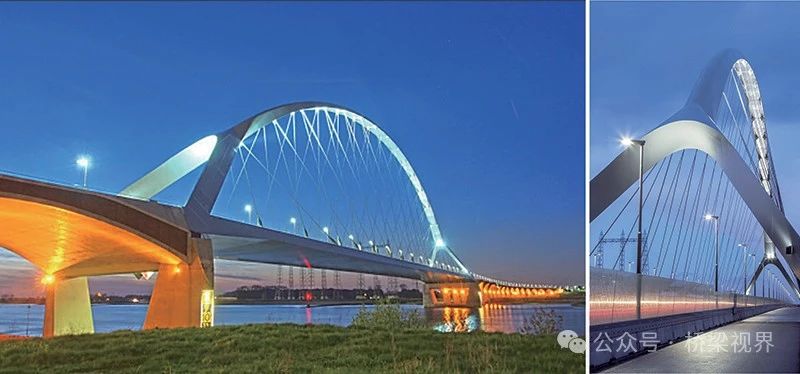

The Nijmegen City Bridge in the Netherlands, completed in 2013 with a main span of 285m and an arch rise of 60m (Figure 16), has a width ranging from 27.6m to 33.9m. The deck is a box structure with a girder height of 1.77m at the centerline. The two steel main longitudinal girders are box structures with a height of 2.2m. The main arch rib splits into an “A” shape near the deck, with the arch rib filled with foam concrete and varying in height and width. It is connected to the main longitudinal girders by 2×30 suspenders in a network arrangement. The sum of the arch rib and tie girder heights to the span ratio (λ2) is 1/71. A temporary support was erected on one riverbank to assemble the arch bridge structure, which was then transported and installed using a floating vessel.

The Bughrinsk Bridge in Russia, opened in 2014 (Figure 17), is the world’s largest span network tied-arch bridge with a main span of 380m. The bridge is 36.9m wide, with six lanes in both directions totaling 32.5m and 1.5m wide sidewalks on both sides. The arch rise is approximately 72.7m, with a rise-to-span ratio of 1/5, and the arch axis is a 300m radius circular arc. The arch ribs are inclined at 12° with a box cross-section of 2m×3.9m (width×height) and connected by high-strength bolts at the segment joints. The steel tie girders have a double box and double I-beam cross-section, and the deck is an orthotropic steel deck. The main bridge has 156 network suspenders, with the arch anchor points spaced 10m apart and a uniform inclination angle of 60°. The construction method for the main arch involved incrementally launching the arch ribs along a vertical curved line with a radius of 290m. From a landscape perspective, the proportion of the main span to the river width is well-balanced, and the arch form is a symbolic architectural element of the city of Novosibirsk, also featured on the city’s coat of arms. Thus, the arch bridge design also symbolizes the continuation of the city’s history.

As China’s future transportation infrastructure continues to develop, there will be a significant amount of bridge construction projects. With China’s vast territory and diverse bridge construction environments, arch bridges, as an important bridge type, have enormous development potential due to their rich diversity, requiring continuous progress and expansion in both technology and art. As functional and landmark structures, bridges are imbued with strong aesthetic attributes, often attracting public attention. Arch bridges are rhythmic structures that harmonize more easily with the environment than other bridge types, with their exterior forms and rhythmic variations better aligning with people’s aesthetic preferences. Therefore, in addition to fulfilling their connectivity function, arch bridges, whether spanning rivers, traversing valleys, or crossing cities, should strive to become architectural artworks with unique charm.

Published in / Bridge Magazine

2024 Issue 1, Total No. 117

Author / Chao-Yu Shao Author’s

Institution / Shanghai Municipal Engineering Design & Research Institute