My Profile

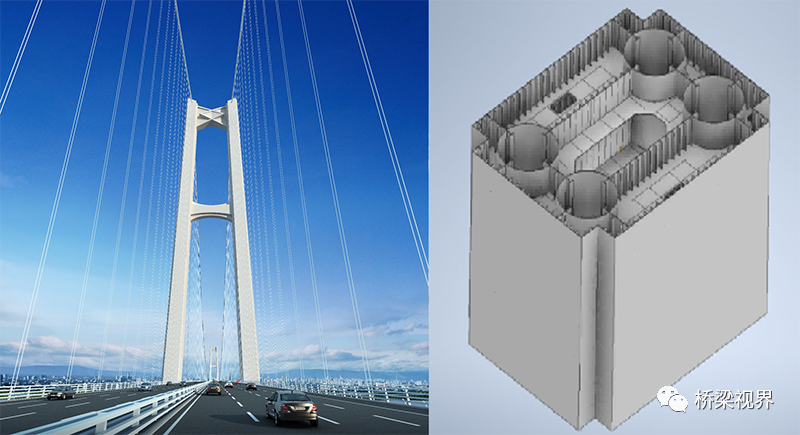

- Name: Changjingao Yangtze River Bridge

- Birthday: Under Construction / Completion in September 2028

- Origin: Jiangsu Province

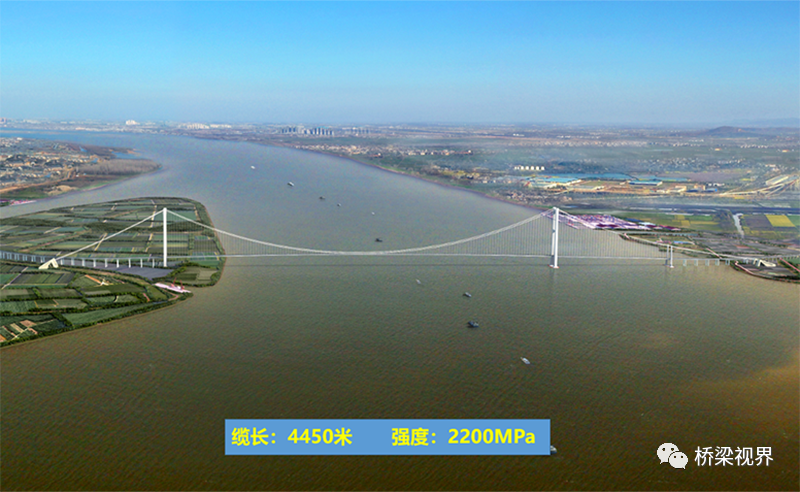

- Length: The cross-river segment is 7,859 meters long, including a 2,300-meter main span for the south navigation channel bridge and a 1,208-meter main span for the north navigation bridge.

- Type: Cable-stayed Bridge

- Features: Large-scale project, large bridge span, high construction difficulty, high safety risks, many large equipment, high environmental protection requirements

- Construction Unit: Jiangsu Provincial Transportation Engineering Construction Bureau

- Design Units: CCCC Highway Consultants Co., Ltd., Hudee Design Group Co., Ltd.

- Construction Units: CCCC Second Harbour Engineering Bureau Ltd., China Railway Bridge Bureau Group Co., Ltd., CCCC Road and Bridge Construction Co., Ltd., Sichuan Road and Bridge Construction Group Co., Ltd., CCCC First Highway Engineering Group Co., Ltd., China Railway Construction Bridge Engineering Bureau Group Co., Ltd., China Railway Shanhai Bridge Group Co., Ltd., China Railway Baohui Bridge Group Co., Ltd., Shanghai Zhenhua Heavy Industries Co., Ltd., Zhenjiang Blue Whale Technology Co., Ltd.

My Uniqueness

The Changjingao Yangtze River Bridge connects the three cities of Suzhou, Taizhou, and Nantong. It starts from the intersection of Shizhuang Town in Rugao City, Nantong with the Shanghai-Xi’an Expressway, heads south through the Shizhuang Industrial Park and Rugao Port Area, enters the Yangtze River at the Huatai Heavy Machinery Factory Area in Rugao, crosses the Rugao Middle Stream of the Yangtze River, passes through Minzhu Island in Jingjiang City, Taizhou, crosses the main navigation channel of the Yangtze River, and lands approximately 400 meters upstream of the Zhangqiao Ferry Terminal in Zhangjiagang City, Suzhou. It then continues southward along the existing and planned Corridor of Provincial Highway 259, terminating at the Chenyang Interchange of the Shugang Expressway, connecting to the existing Zhangjiagang Shugang Expressway. The total length of the route is 29.849 kilometers.

▲ The Changjingao Yangtze River Bridge under construction

Six “World’s Firsts”

As the control project of the cross-river segment of the Changjingao Yangtze River Bridge, the south navigation channel bridge considered the river conditions, navigation, flood control, and other construction conditions and control factors during the preliminary research stage. Firstly, it should avoid setting bridge piers within the 12.5-meter deep-water navigation channel and its swing range and comprehensively consider adapting to future changes in the navigation channel. Secondly, it should control the number and scale of large water-obstructing components within the river area to meet the requirements of river conditions and flood control, thus setting six “world’s firsts.”

1. World’s Largest Span Cable-Stayed Bridge

The main span of the south navigation channel bridge is 2,300 meters.

2. World’s Tallest Cable-Stayed Bridge Tower

The main tower of the south navigation channel bridge is 350 meters high.

3. World’s Longest High-Strength Main Cable

The length of the main cable of the south navigation channel bridge is 4,450 meters, with a main cable strength of 2,200 MPa.

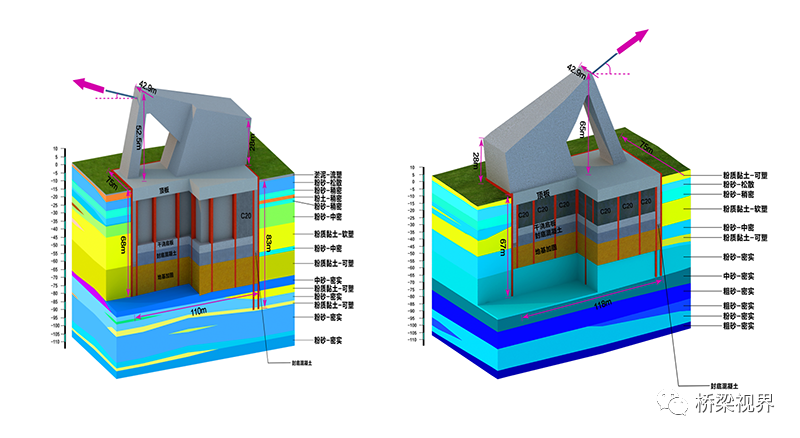

4. World’s Largest Composite Diaphragm Wall Anchor Foundation

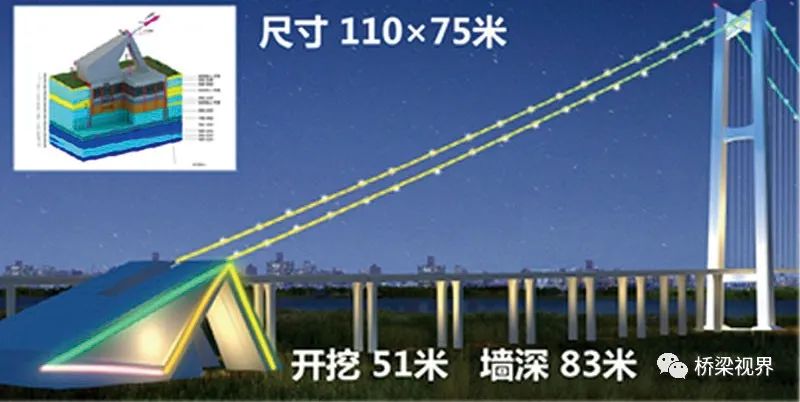

The south anchor foundation of the south navigation channel bridge is 110 meters long, 75 meters wide, with an 83-meter-deep diaphragm wall, and a 51-meter excavation depth for the foundation pit.

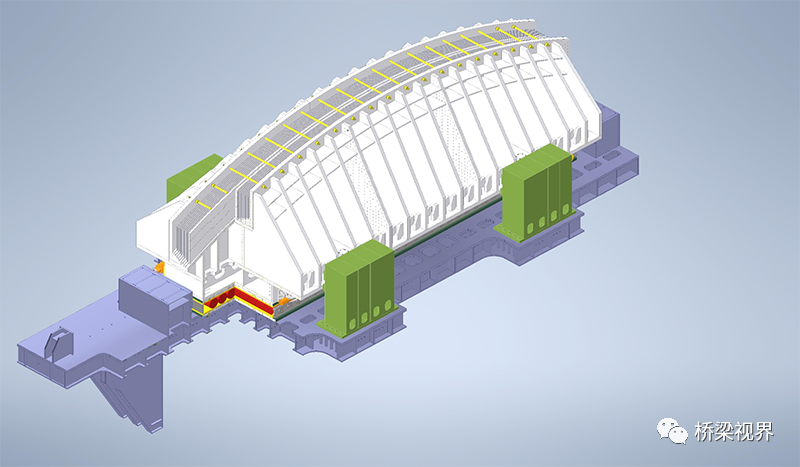

5. World’s Longest Continuous Steel Box Girder

The south navigation channel bridge is a 2,300+717-meter two-span continuous steel box girder cable-stayed bridge, with a maximum continuous length of 3,017 meters.

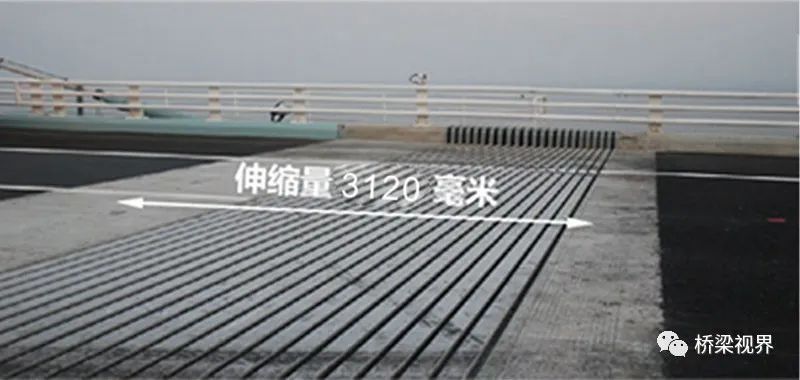

6. World’s Largest Displacement Expansion Joint

The south navigation channel bridge has expansion joints with a displacement of 3,120 millimeters installed at both ends of the steel box girder.

Six “World’s Firsts”

Based on fully considering factors such as the self-weight of structures, temperature, vehicle loads, geological conditions and groundwater levels, seismic requirements, wind-induced vibration effects, metal corrosion, construction risks, and existing technical reserves, and through theoretical calculations, special studies, model tests, and process tests, the construction of the south navigation channel bridge will achieve six “world’s firsts.”

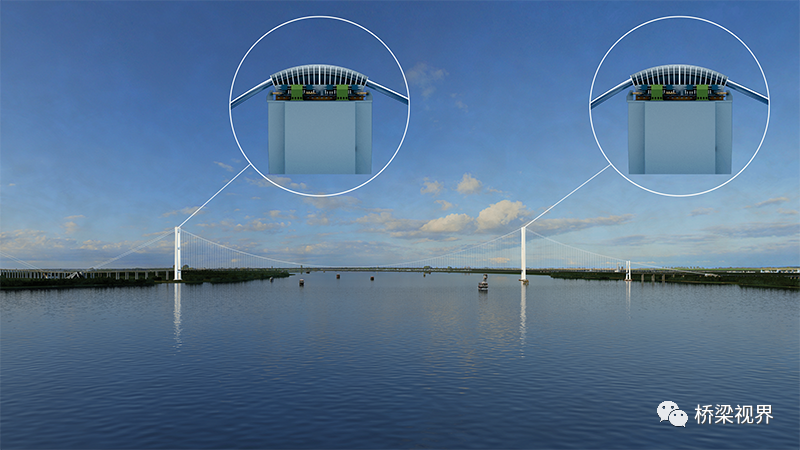

1. The First Self-Balancing Main Cable Structure System for Ultra-Large Span Cable-Stayed Bridges

Adopting a self-walking roller-type main cable saddle structure, it achieves self-balancing of the horizontal component forces of the main cables on both sides and the rolling friction force of the cable saddle under common loads such as temperature and vehicle loads. The horizontal force is the minimal rolling friction force, effectively relieving the significant unbalanced horizontal force at the tower top caused by the asymmetric super-long side span, effectively improving the force condition of the cable tower, and reducing the foundation scale.

2. The First Ultra-High Steel Box-Concrete-Filled Steel Tube Composite Cable Tower

While fully utilizing the excellent compressive performance of concrete-filled steel tubes, it can achieve a 50% reduction in the self-weight of the tower body, enabling prefabricated construction with factory manufacturing and on-site hoisting of the cable tower segments. The project quality can be fully guaranteed, and cracking of the cable tower can be effectively avoided.

3. The First Ultra-Large-Scale Support-Transfer Structure Composite Diaphragm Wall Anchor Foundation

The double-layer diaphragm wall + infill forms a composite structure, ensuring the overall integrity and safety of the foundation pit excavation. The foundation is divided into compartments for underwater excavation and underwater sealing, reducing the risks of foundation pit excavation. Through deep foundation reinforcement treatment, the foundation excavation depth and construction risks are significantly reduced. The diaphragm wall trench section adopts rigid joints to ensure the overall integrity of the foundation, serving as both a retaining structure and a permanent load-bearing structure.

4. The First Ultra-Large Self-Walking Prefabricated Cable Saddle

Adopting roller friction with an extremely low friction coefficient to achieve the self-walking function, and by setting longitudinal stoppers, the cable saddle only experiences limited displacement, ensuring structural safety. For occasional actions such as centennial winds (strong winds) and earthquakes, damping devices are used to keep the cable saddle in a braking state, ensuring the safety and stability of the entire bridge.

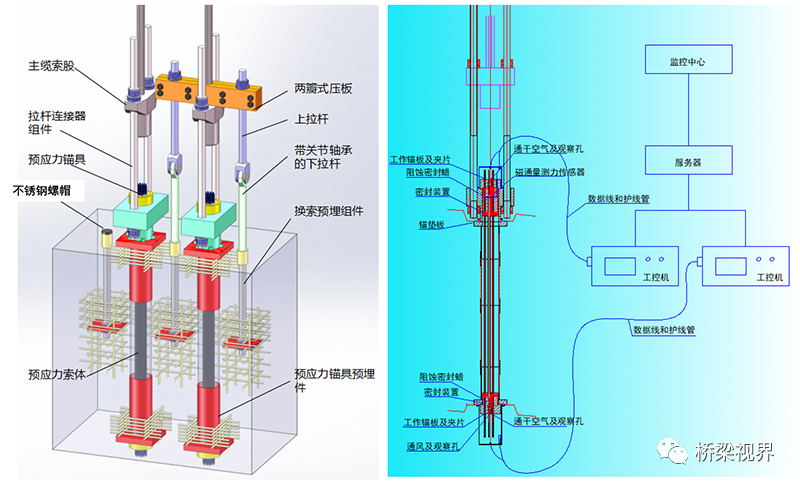

5. The First Intelligent Sensing Replaceable Anchor System

By pre-embedding fixed-end anchors on both sides of the front anchor face connector, and installing self-locking tool bars and double-leaf bearing plates during replacement construction, the entire replacement of the connector, bar components, and prestressed anchor system can be achieved. By embedding humidity sensors, detectors, and other monitoring devices, intelligent sensing is realized to better monitor the working condition of the anchor system.

6. The First Integrated Intelligent Anti-Corrosion System for the Entire Bridge

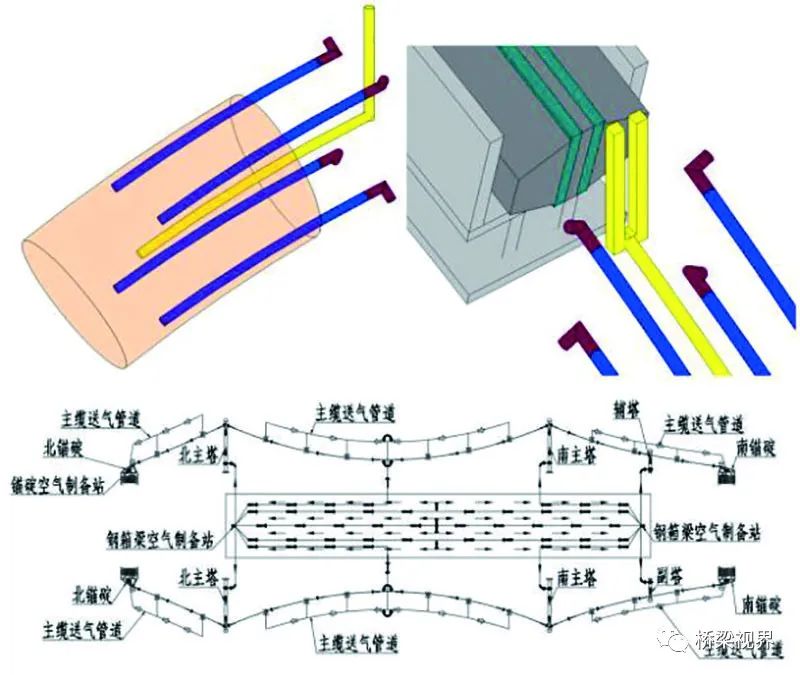

The main cable, saddle room, anchor room, main girder, and cable tower share dehumidification equipment as much as possible, using a station-like form instead of traditional separate dehumidifiers, optimizing the air flow organization, and recycling and reusing dry air. The main cable is equipped with four ventilation ducts on the outside and one ventilation duct in the center, allowing the steel wires of the main cable to be in a low-pressure dry air environment. The entire system has lower energy consumption, easier maintenance, and is more environmentally friendly and green.

The six “world’s firsts” in key technological innovations embody the integrated application of new technologies such as safety risk prevention and control, quality engineering enhancement, intelligent construction, and green and low-carbon practices, highlighting the construction goals of “a benchmark and iconic project for the construction of a strong transportation country in Jiangsu, a representative project leading China’s bridge technology innovation, and a milestone project in the construction of the world’s ultra-large span cable-stayed bridges.”